Day 2 :

- Ceramic Engineering | Ceramic Compounds: Ceramic Materials

Location: Armstrong

Chair

Sergey Sokovnin

Institute of Electrophysics, Russia

Session Introduction

Charles Hetzel

Brookhaven National Laboratory, USA

Title: Ceramics in particle accelerators

Time : 10:45-11:05

Biography:

Abstract:

D J Whitefield

University of the Witwatersrand, South Africa

Title: The use of 3D printing and gelation casting to fabricate complex ceramic parts

Time : 11:25-11:45

Biography:

Abstract:

- Electro-magnetic and Optical Ceramics and Devices | Surface Engineering and Ceramic Coatings | Alloys

Location: Armstrong

Chair

Slawomir Kaczmarek

Westpomeranian University of Technology, Poland

Session Introduction

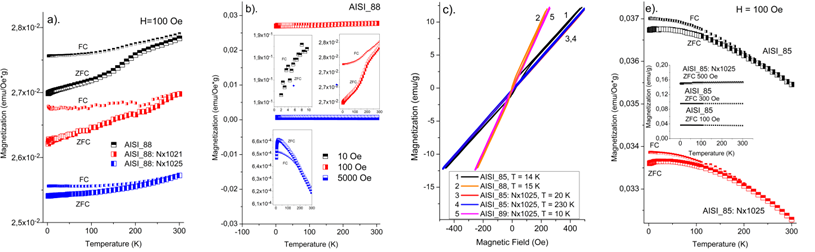

Slawomir M Kaczmarek

Westpomeranian University of Technology, Poland

Title: Influence of nitriding process on magnetic properties of steel ball-like samples

Time : 11:45-12:05

Biography:

Abstract:

Anna Backerra

The Netherlands

Title: Four types of electrons, each allowing matter to behave in a specific way, according to twin physics

Time : 12:05-12:25

Biography:

Abstract:

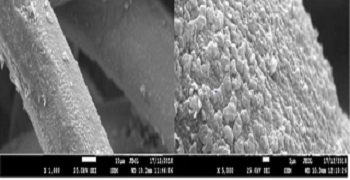

Oloyede O R

Afe Babalola Univerity, Nigeria

Title: Improving wear performance of multi-layer electroless Ni-based coating using laser heat treatment

Time : 12:25-12:45

Biography:

Abstract:

Osama M Ibrahim

Kuwait University, Kuwait

Title: Formation of aluminum-oxide layer on the surface of Fe-Cr-Al fibers

Time : 13:15-13:35

Biography:

Abstract:

Oloyede O R

Afe Babalola Univerity, Nigeria

Title: Effect of heat treatment on the morphology and mechanical properties of commercial aluminium 6063 alloy

Time : 13:35-13:55

Biography:

Abstract:

- Advanced Materials| Composite Materials

Location: Armstrong

Chair

P N De Aza

Miguel Hernández University, Spain

Session Introduction

Kenji Uchino

The Pennsylvania State University, USA

Title: Piezoelectric composites

Time : 14:15-14:35

Biography:

Abstract:

Nasrin Al Nasiri

Imperial College London, UK

Title: The oxidation behaviour of a melt infiltrated (MI) SiC/SiC matrix composite (CMC) at high temperature in air

Time : 14:35-14:55

Biography:

Abstract:

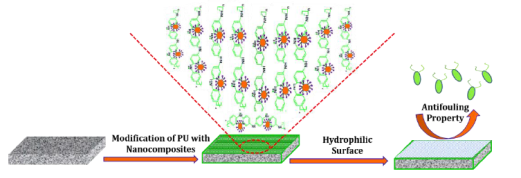

Vandana A Mooss

Savitribai Phule Pune University, India

Title: PANI-ZnO nanocomposites embedded polyurethane films for antifouling applications

Time : 15:30-15:45

Biography:

Abstract:

- Poster presentations

Location: Armstrong

Session Introduction

Charles Hetzel

Brookhaven National Laboratory, USA

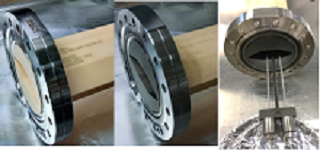

Title: Ceramics in particle accelerators

Biography:

Charles Hetzel has held the title of Lead Project Engineer for a design and manufacturing organization which produced automated industrial machinery prior to joining NSLS-II. Upon joining the NSLS-2 project he was responsible for the design, procurement and fabrication of the storage ring vacuum chambers including the integration of these chambers into the magnet-girder assemblies and final installation in the storage ring tunnel. He also managed the production of the rf shielded bellows for interconnecting the storage ring vacuum chambers as well as the photon absorbers which protect critical components. He took over as the Vacuum Group Leader at NSLS-2 in 2014 and continues to resource plan and schedule major installation efforts. Most recent efforts are focused on the design and development of a thin film coating system for ceramic vacuum chambers.

Abstract:

Lewis J Print

University of Strathclyde, UK

Title: Using pre-ceramic polymers in the joining of silicon carbide ceramics

Biography:

Lewis J Print is pursuing his PhD in Polymer Chemistry at the University of Strathclyde. Under the supervision of Dr John J Liggat L. Print focuses on the development of methodologies to adhere silicon carbide ceramic using polymers for high temperature applications. This includes utilising a variety of analysis technique to characterise these polymers: including thermal analysis, thermal degradation and spectroscopy techniques. He also has interests in biodegradable polymers, the mechanical and physical properties of various polymers and novel applications of IR spectroscopy.

Abstract:

Organic-inorganic hybrid materials are becoming increasingly more useful in industry for combining polymers with ceramics. The resulting material offers a variety of characteristics of significant value to industry, including high mechanical strength and thermal resistivity. Using these hybrid materials, ceramics can adhere together effectively. Currently, an organic adhesive resin system is used to join silicon carbide (SiC) rods together. However, due to their toxicity there is a necessity to remove these from the application. Comparing the organic resins, as a joining agent, with pre-ceramic silicon based polymer resulted in a large difference in the quality of the joints produced from SiC rods. The rods mechanical strength and resistivity across the weld were compared as factors. A four-point flexural test and a four-point terminal resistivity test were used for this analysis. These polymer materials were analysed using Fourier-Transform infrared spectroscopy (FTIR) and Differential scanning calorimetry (DSC) to determine the curing reactions occurring in both systems. Thermogravimetric analysis (TGA) was also performed to determine polymer retention at 800°C. Additionally, these welds were compared under an optical microscope to investigate the difference in the integrity of the welds produced. X-ray powder diffraction (XPD) was also used to analyse the polymer: ceramic conversion undergone at high temperatures for the silicon based polymer.The new silicon polymer rods showed much better strength and resistance values compared to the organic resin joined rods. Their integrity and retention at high temperatures also showed improvements over the current system used. It can be determined from this that they can be successfully used in this system as a replacement for the organic organic resin. This makes the materials much safer and much more effective as a joining adhesive for the SiC rods.

Chen Barad

Ben-Gurion University, Israel

Title: Influence of galia (Ga2O3) addition on the phase evolution and grain growth behavior of voided yttria stabilized zirconia (YSZ) powder

Biography:

Chen Barad is pursuing her Graduation and has expertise in sol-gel synthesis and in the field of ceramic materials. Her previous knowledge and experience in chemistry and chemical engineering creates new pathways for research in the field of ceramic materials. She has experience in research of YSZ powders and other zirconia based powders for energy applications (solid oxide fuel cells and thermal barrier coatings), designing powder particle morphology and analyzing XRD patterns.

Abstract:

The effect of galia addition to diverse metal oxides has been occupying researchers in the aspects of preparation finer powders and improving sintering of advanced ceramic materials for high temperature applications. Pure galia shows polymorphism, but at high temperatures only its monoclinic form is thermodynamically stable. Moreover, by adjusting the ambient atmosphere, oxygen vacancies are formed in the non-stoichiometric gallium oxide structure which is advantageous in oxygen ion conducting applications. However, in spite of being the most popular solid oxygen conducting electrolyte, the addition of galia to YSZ has not been researched profoundly. The effect of a galia (Ga2O3) addition on the crystallographic phase transformations and the grain growth behavior of yttria stabilized zirconia (YSZ) were investigated regarding powders containing different amounts of galia in the range of 0-25 mol %. Ternary compositions of galia- YSZ sponge-like cryogels were prepared by the sol-gel method combining freeze-drying process and calcination of dried powders at different temperatures for two hours in air. Crystallographic phase transitions were analyzed via X-ray diffraction (XRD) and exceptional powder particle morphology of internal nano voids derived from the freeze-drying technique was investigated by using Scanning Transmission Electron Microscope (STEM). The effect of Ga2O3 addition to 8YSZ was found to be similar to that of Ga2O3 addition to zirconia sol-gel powders. The addition of Ga2O3 to 8YSZ inhibited the crystallization of 8YSZ extending the amorphous range and increasing activation energy for the growth process of grains. Regarding solgel powder morphology, it was found that by coupling the sol-gel synthesis with the freeze-drying technique it is achievable to preserve unique nano-voids in the ternary it is achievable to preserve unique nano-voids in the ternary system of 8YSZ+Ga2O3.