Slawomir M Kaczmarek

Westpomeranian University of Technology, Poland

Title: Influence of nitriding process on magnetic properties of steel ball-like samples

Biography

Biography: Slawomir M Kaczmarek

Abstract

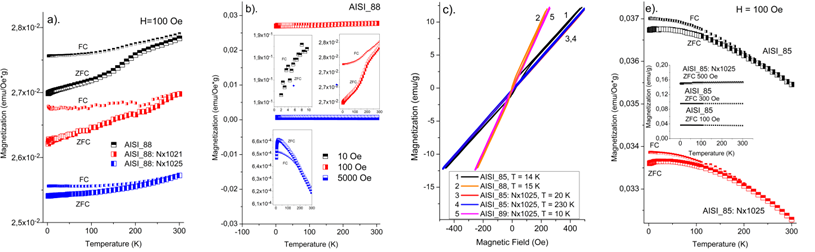

The nitriding is a thermo-chemical treatment of the steel which improves its wear resistance, corrosion resistance and hardness. Gas nitriding is a thermo-chemical processing of steel implemented in the temperature range of 400-600ºC. The nitriding process takes place in conditions of forced flow of the nitriding atmosphere. At a constant temperature, depending on the value of the nitriding potential, the subsurface iron nitride layer formed may consist of only the γ'-Fe4N phase or a mixture of phases γ’-Fe4N and ε-Fe2–3N. A diffusion zone is formed under the iron nitride layer, in which nitrogen is dissolved interstitially in a ferritic matrix and carbonitrides of iron and alloying elements occur. The thickness and phase composition of the layers of iron nitrides are decisive on the resistance to corrosion and the abrasive wear of steel after nitriding. The diffusion zone, in the case of alloy steels, increases the fatigue strength of steel. The surface layer (core shell) appearing after nitriding treatment affects the magnetic and electric properties of the steel. Several AISI steel balls with different diameters and thermal treatments (Nx1021, Nx1025) were investigated using FMR and SQUID techniques. FMR spectra revealed wide and intense signals visible in temperature range from helium to room one. Position of each signal, being far from geff~2, as expected for iron magnetic ions, indicated on complex nature of responsible magnetic centers. Magnetization measurements have shown non-uniform behavior of the investigated samples with temperature variation. For most of them, having carbon content higher than 0.13 wt. %, the rise of magnetization with increasing temperature was observed, which strongly depended on applied magnetic field. For samples with carbon content lower than 0.13%, a drop in

magnetization was observed with increasing temperature, as usually for AISI steel. Significant magnetic anisotropy has been revealed, decreasing with increasing temperature.

The magnetization, M(T), dependence of the AISI_85-89 samples: a). AISI_420C (88) sample: precursor, Nx1021 and Nx1025 nitriding processes for H=100 Oe, b). AISI_420C (88) sample for H=10, 50 and 5000 Oe, c). hysteresis loops for AISI_1010 (85) (14 K) and the same sample underwent to Nx1025 process (20 and 230 K), hysteresis loops for AISI_420C (88) (15 K) and AISI_1085 (89): Nx1025 (10 K), and, e). M(T) dependence of AISI_1010 (85) and AISI_1010 (85) (Nx1025) samples for H=100, 300 and 500 Oe.