Osama M Ibrahim

Kuwait University, Kuwait

Title: Formation of aluminum-oxide layer on the surface of Fe-Cr-Al fibers

Biography

Biography: Osama M Ibrahim

Abstract

The objective of this paper is to investigate the formation and adhesion of a protective aluminum-oxide layer (alumina) on the surface of Iron-Chromium-Aluminum (Fe-Cr-Al) alloy. The oxide scale layer was developed via multi-stage thermal oxidation that consists of the following heating stages: at 930°C for one hour, at 960°C for 1 hour, and finally at 990°C for 2 hours for a total of 4 hours, which represents one heat treatment cycle. Thermogravimetric Analyses (TGA) was performed to quantify the development of the oxide layer. The first sample was tested for one cycle of 4hours; while the second sample was tested for 18 repeated cycles of 4 hours for a total of 72 hours. Both

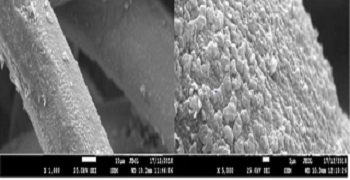

samples gained weight due to oxidation.Scanning electron microscope (SEM) images show that one heat treatment cycle, results in the formation of predominantly alumina platelets like and whiskers. After 18 heat treatment cycles, however, the surface of the oxide scale layer becomes smoother and more uniform. Following vibration for1 hour consists of 50Hz for 30min, 100Hz for 15min, and finally at 150Hz for 15min and minimum handling of the two samples, peeling or spalling of the protective oxide layer was observed. Energy Dispersive spectroscopy (EDS) analysis of the heat-treated samples of Fe-Cr-Al sintered metal fibers confirmed the high aluminum content on the surface of the protective oxide layer and the low aluminum content on the exposed base metal alloy surface.

Figure : FeCrAl fiber heat treated for 72 hours