Sergey Sokovnin

Institute of Electrophysics, Russia

Title: Producing nanopowders for functional ceramics by pulsed electron beam evaporation method in vacuum

Biography

Biography: Sergey Sokovnin

Abstract

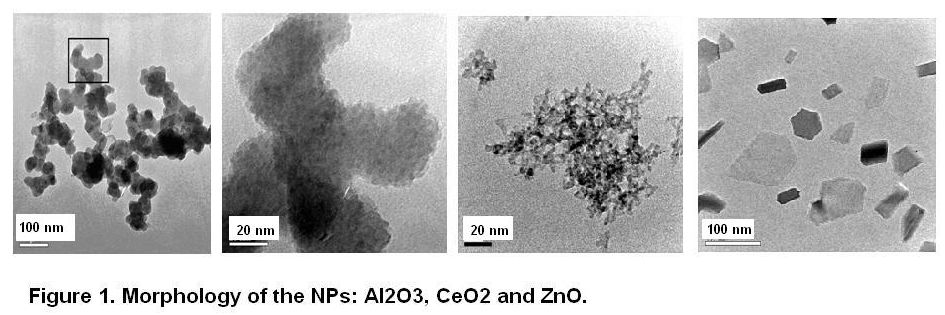

By method of pulsed electron beam evaporation in vacuum of targets from bulk state compounds of plain and complex oxides (ZnO-Zn, Al2O3, SiO2, CeO2,YSZ (Y2O3-8% Gd2O3 est.) and also fluorides (CaF2 and BaF2) nano powders (NPs) with a high specific surface were produced. The morphology magnetic, thermal and luminescence characteristics of NPs were measured. Than have studied the properties of ZnO ceramics sintered from the ZnO-Zn NPs to establish the influence of NPs prehistory on the luminescence and dilatometry properties properties of ceramics produced from them. Pressing was performed on uniaxial presses: static and the magnetic pulsed one. Sintering of ceramics was produced in air by heating to 1200°C in 60 min. Maximal density of the ceramics did not exceed 81, 25% of the theoretical density. The behavior of the shrinkage curves of ZnO-Zn NPs depends on their prehistory. The suppression of the ultraviolet emission in NP obtained by electron beam evaporation, and in ceramics sintered of them was established. Besides, two types of ZnO ceramics were fabricated and characterized by XRD, SEM methods. The radioluminescence spectra were measured within the 300-550K range.The thermostimulated luminescence (TSL) glow-curves were measured after X-ray irradiation at 300K. It was concluded that the complex overlapping peak within the 320-450 K temperature range consists of two components (~360-375K and 400-420K). The ratio of component intensities differs in both ceramics. The positions of high temperature TSL components (480-520K) also differ in both samples; therefore not only sintering conditions but also the properties of the initial powder are very important for characteristics of TSL. A linear dependence of peak intensity on irradiation dose was observed up to ~3 kGy for ceramic 1 and up to 9 kGy for ceramic 2.