Day 1 :

Keynote Forum

Jesús Ma Rincon

Instituto de Ciencias de la Construcción Eduardo Torroja, Spain

Keynote: Glass-ceramic composites from the extrinsic to the intrinsic point of view

Time : 09:30-10:15

Biography:

Prof. Dr. J Ma Rincón is a Senior Research Professor (Profesor de Investigación) at the Instituto E. Torroja de Ciencias de la Construcción, CSIC, Madrid, where he is the founder and Head of the Glass- Ceramics Laboratory. He was General Secretary of the Spanish Glass and Ceramic Society and Editor - in- Chief of Bol. Soc. Esp. Ceram.Vidr. He has conducted electron microscopy on ceramics, glasses and glass-ceramics and their raw materials, being author of seven monograph books and more than 170 papers in glass-ceramics and advanced ceramics. He was invited Prof. Dept. Materials Science and National Electron Microscopy Lab., University Califomia, Berkeley,1984-85 working in zirconial/ mullite composites. Since last 15 years is active in the vitrification and recycling of a wide range of residues, up to simulated radioactive industrial wastes. Recently, he was the past President of the Spanish Soc. of Scientists.

Abstract:

Composite material is a production field that reached, already in the last century, its full development in science, technology and market applications. At the starting of composites materials research, usually only those materials that are composed by a dispersed material into a continuous matrix were considered as “actual composites”. However , this concept has evolved more in recent decades, due to the capability to precipitate into a matrix for internal thermal processing or phase transformations of several heterogeneous shaped materials into several matrices and/or respectively; that is the case of the glasses and glass-ceramic composites. Thus, inside the “non-metal or inorganic composites”, both glasses and glass-ceramics which have given rise to the fine or advanced ceramics, the “glass-ceramic composites” can be considered such as composites. To this respect, there are two ways for considering composites in this research: a). The extrinsic, more traditional composites, by embedding a phase into another phase or b) to promote the phase transformation into a glassy or vitreous phase for precipitating very small crystallites (even nanocrystals) into the glass, giving rise to an “intrinsic glass-ceramic composite”. Some of researches carried out in last decades of the author in this type of composites are reviewed and possibilities for applications for this material are discussed. In fact, this wide family of composites can be very useful for construction or for industrial applications. Even more, in recent years, the “composite concept” for materials and for processes are emerging as one promising solution for using this technology to immobilize some radioactive wastes into composite glass-ceramic matrices with long term stability.

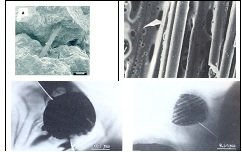

Figure 1: Micrographs from several inorganic composites:

a) FPP fibers in CSH matrix (SEM);

b) SiC fibers in basalt GC (SEM) c) ZrO2 in mullite sintered glass- ceramic (TEM)

Recent Publications :

- Callejas, J. Rubio, J. Ma. Rincón, J.L. Oteo (1990), Estudio previo de materiales compuestos a base de basaltos reforzados con fibras de CSi (NICALON). In: Ciencia y Tecnología de los Materiales Cerámicos y Vítreos, España’89, Castellón, Ed. Faenza Editrice Ibérica, SL., pp: 79-84

- Cáceres,J.M., J. E. García- Hernández y J. Ma. Rincón (1996). Characterization of fibers as rockwool for insulation obtained from canary islands basalts. Mater. Construcc. 46 , 242-243: 61-78

- Rincón , J.Ma. (2002). Glasses, glazes and glass-ceramics at the starting of the millennium. Key Engineering Material 206-213, 2: 2039-2044

- García Santos , A., J. Ma. Rincón, Talero, R. (2005). Characterization of a polypropilene fibered cement composite using ESEM, FESEM and mechanical testing. Constr. Build. Mater. 19 : 396-403

- Rincón,J.Ma. M. Romero, Mª. S. Hernández- Crespo, R. Talero, García-Santos,A. ESEM and EDS microanálisis in a FPP/ cement matrix composite, In: Science and Technology of Composite Materiales COMATCOMP-09, Eds. A. Güemes et al., San Sebastian., Vol 1 . 399-402

Keynote Forum

Seiki Chiba

Chiba Science Institute, Japan

Keynote: Progress and Current Status of Electroactive Polymer Transducers

Time : 10:15-11:00

Biography:

Seiki Chiba was Executive Director for Advanced R&D Project Development, Stanford Research Institute (SRI International). He served on SRI for 20 years. He was supervising advanced R&D programs including Japanese Government projects. Now, he is CEO of Chiba Science Institute. He is the author or coauthor of more than 300 publications in various areas including artificial muscle actuators & generators, hydrogen safety, and high temperature membranes for hydrogen production. He has a PhD in Metallurgy & Material Science from the University of Wales (Britain). He received IAAM Medal for outstanding contribution in the field of Advanced Material Science and Technology.

Abstract:

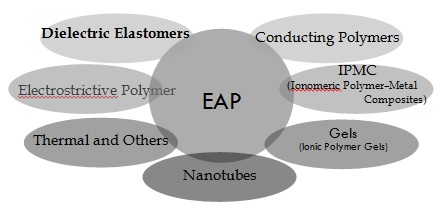

Soft transducers made of synthetic or natural materials, capable of converting physical or chemical energy into mechanical work in response to various environmental stimuli such as salt, pH, humidity, heat, solvent, light, magnetic or, electric field, and light, have been gaining attention for biomimetic actuators. Some of the transducers have also been shown to operate in reverse as a generator. This lecture discusses electroactive polymer (EAP) transducers (see Figure 1). EAP can be generally classified into two categories: Wet (ionic) and electronic (electronic field responsive). Wet polymers use electrically driven mass transport of ions or electrically charged species to effect a change in the shape (or vice versa). Electronic polymers use an electric field to effect a shape change by acting directly on charges within the polymer (or vice versa). Each type of electroactive polymer has advantages and disadvantages for particular applications. Wet polymers typically can exert relatively high pressures and can be driven by low voltages. However, they are relatively slow and limited in size (since they are dependent on molecular transport), require high current and relatively energy inefficient. They can operate best over a narrow range of temperatures and must often be kept moist. In contrast, electronic polymers can be fast, efficient, and relatively insensitive to temperature and humidity fluctuations. These polymers can operate at relatively high voltages and low currents, which usually requires additional voltage conversion components but makes the size and capacity of wires and interconnects lighter and less critical. A type of field-activated EAP transducer that embodies the desirable properties of polymer is dielectric elastomers (DEs). DEs show considerable promise for harvesting energy from wind, ocean waves, water currents, or even from human motion.

Figure 1: Typical Electroactive Polymers (EAPs)

Recent Publications :

- S Chiba, M Waki, R Kornbluh and R Pelrine (2011) Current status and future prospects of power generators using dielectric elastomers. Smart Materials and Structure. 20(12):124006.

- S Chiba et al. (2017) Simple and robust direct drive wave power generation system using dielectric elastomers. Journal of Materials Science and Engineering B. ISSN 2161-6221

- Sessions: Ceramics and Glasses | Composite Ceramic Materials | Ceramic Coatings

Location: Burgos

Chair

Nicolas Tessier-Doyen

SPCTS laboratory, France

Session Introduction

Nicolas Tessier-Doyen

SPCTS laboratory France

Title: Organized silicate-based composite materials: Mechanical and thermal properties related to processing

Time : 11:20-11:50

Biography:

Nicolas Tessier-Doyen has developed an expertise in the field of composite ceramic materials especially in the characterization of mechanical and thermal properties and in the processing of silicate-based materials by controlling their microstructure and the texturation phases. Since 15 years, his research activity is focused on the optimization of macroscopic properties of multi-phase ceramics taking into account each contribution microstructural parameters and the shaping process.

Abstract:

Ceramic shaping processes such as uniaxial pressing, tape casting or extrusion favor the orientation of clay platelets in silicate materials. For example, kaolinite and muscovite phyllosilicates exhibit an anisotropic structure having attracted considerable interest in optimizing materials characteristics. As a consequence, mechanical and thermal properties can be significantly different in function of considered directions. However, controlling thermal treatment is also essential in such materials to keep the anisotropic microstructure of specimens after sintering and to optimize amount, organization and size of the occurred mullite phase. Moreover, adding a slight proportion of a second phase such as low cost silicate-based long fibres can also contribute to enhance mechanical properties. In this work, two types of silicate ceramic materials are presented: Clay-based materials obtained by extrusion processing anisotropy at macroscopic scale has been evidenced by thermal conductivity (laser flash method) and Young’s modulus (pulse echography technique) measurements denoting a decrease of anisotropic degree when the temperature of sintering increases. These results are in agreement with significant transformations occurring in kaolinite phase; multi-layer ceramic composites reinforced with silicate-based fibres, it has been shown that mechanical properties of final substrate specimens are closely related to the organization degree of mullite crystals, due to the formation of a specific mullite network at different scales of the microstructure. The anisotropy of elastic properties has also been evidenced in directions parallel and perpendicular to the casting direction. Despite the very low proportion of added fibres (less than 5wt.%), Young’s modulus and stress to rupture are improved to about 20 and 50% respectively. Moreover, fracture toughness values are multiplied at least by 2 compared to the single substrate layer because of crack defection and crack bridging mechanisms occurring at the fiber/matrix interface.

Recent Publications

- Tessier-Doyen N, Bourret J, Guinebretière R, Joussein E, Smith DS (2015) Anisotropy of thermal conductivity and elastic properties of extruded clay-based materials: Evolution with thermal treatment. Applied Clay Sciences 116:150-157.

- Tessier-Doyen N, Bourret J, Naï-Ali B, Pennec F, Alzina A, Peyratout CS, Smith DS (2013) Effect of the pore volume fraction on the thermal conductivity and mechanical properties of kaolin-based foams. J. Eur. Ceram. Soc. 33 (9):1487-1494.

- Tessier-Doyen N, Deniel S, Dublanche-Tixier C, Chateigner D, Blanchart P (2010) Processing and characterization of textured mullite ceramics from phyllosilicates. J. Eur. Ceram. Soc. 30:2427-2434.

- Tessier-Doyen N, Boussois K, Blanchart P (2013) Anisotropic kinetic of the kaolinite to mullite reaction sequence in multilayer ceramics. J. Eur. Ceram. Soc. 33:243-249.

- Tessier-Doyen N, Boussois K, Blanchart P (2014) High toughness silicateceramics. J. Eur. Ceram. Soc. 34:119-126

Maik Finsel

University of Hamburg, Germany

Title: Synthesis and thermal stability of monodisperse ZrO2@SiO2 core-shell submicron particles

Time : 11:50-12:20

Biography:

Maik Finsel conducted his Master’s thesis investigating the mechanical properties of nanoparticle composites (University of Hamburg) and spent one semester in Denmark (Southern University of Denmark, Odense) working on transition metal complexes. He gained expertise in the synthesis and characterization of doped and undoped zirconia microparticles doing his PhD at the University of Hamburg, Germany. He also works on the encapsulation of ceramic microparticles with silica and alumina to achieve dielectric core-shell particles for photonic high-temperature applications.

Abstract:

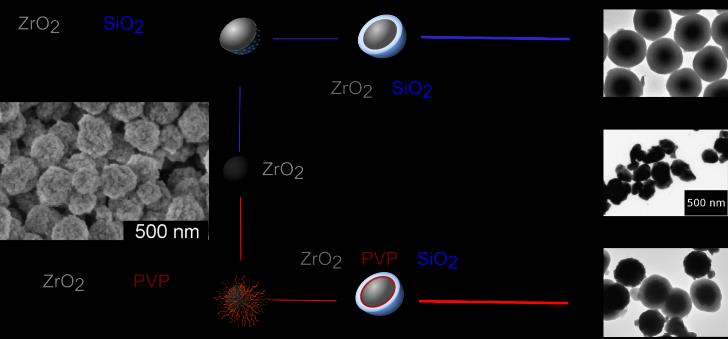

In recent years, zirconia (ZrO2) micro- and sub-microparticles have attracted considerable attention due to their outstanding properties, including chemical inertness, thermal stability and high refractive index. They are suited for a broad variety of applications ranging from fuel cells, catalysis, electro- and bio ceramics to building blocks in photonic structures. The latter are promising materials for high-temperature applications, including thermal barrier coatings (TBC) and structural colors (SC). The thermal stability, surface smoothness and optical properties of zirconia particles can be improved or modified by encapsulation with a suitable shell material. By using different types of shells, e.g. Al2O3, SiO2, TiO2 or polymers, desired properties of the resulting core-shell composites for various applications are achievable. For example, silica shells ensure a strong refractive index contrast for application as structural colors. Previously, it was shown that silica shells could be grown on ZrO2 cores after surface modification with organic additives (polymer, citric acid). However, such additives most likely preclude high-temperature applications. For the preparation of ZrO2@SiO2 core-shell sub-microparticles, we developed a straightforward approach without the need of additional organic capping agents by using SiO2 seeds as self-adhesive layer. The zirconia core particles were synthesized according to the sol-gel method by Widoniak et al. modified to achieve smaller diameters. In the pre- encapsulation step, silica seeds are formed on the core surface. The silica shell can then grow smoothly on its self-adhesive layer and its thickness is controlled by successive addition of silica precursor. The obtained core-shell particles withstand temperatures up to 1000°C whereas size-comparable zirconia particles disintegrate when heated to 800°C. Also, core-shell particles synthesized using polyvinylpyrrolidone (PVP) as interfacial coupling agent disintegrate when heated to 800°C, most likely due to decomposition of PVP. Using XRD, SEM and cross-sectional TEM characterization, we show how grain growth and phase transitions are influenced by the SiO2 encapsulation of ZrO2 submicron particles. Additionally, the thermal stability can be improved by doping zirconia cores with yttrium or yttrium/lanthanum, as recently shown for zirconia microparticles

Figure 1: Synthesis of ZrO2@SiO2 core-shell particles with PVP as coupling agent (red arrows, according to previous work) and with SiO2 seeds as self-adhesive layer (blue arrows, novel method). After temperature treatment at 1000°C, the shell of the PVP containing particles partially disintegrated whereas most silica shells without interfacial PVP layer stayed intact. Heated zirconia particles (without shell) after 1000°C are shown for comparison (black arrow).

Recent Publications :

- Leib EW, Vainio U, Pasquarelli RM, Kus J, Czaschke C, Walter N, Janssen R, Müller M, Schreyer A, Weller H, Vossmeyer T (2015) Synthesis and Thermal Stability of Zirconia and Yttria-Stabilized Zirconia Microspheres, Colloid Interface Sci. 448:582-592.

- Leib EW, Pasquarelli RM, do Rosário JJ, Dyachenko PN, Döring S, Puchert A, Petrov AY, Eich M, Schneider GA, Janssen R, Weller H, Vossmeyer T (2016) Yttria-Stabilized Zirconia Microspheres: Novel Building Blocks for High-Temperature Photonics, J. Mater. Chem. C 4:62-74.

- Leib EW, Pasquarelli RM, Blankenburg M, Müller M, Schreyer A, Janssen R, Weller H, Vossmeyer T (2016) High-Temperature Stable Zirconia Particles Doped with Yttrium, Lanthanum and Gadolinium, Part. Part. Syst. Charact. 33:645-655.

- Bai A, Song H, He G, Li Q, Yang C, Tang L, Yu Y (2016) Facile synthesis of core-shell structured ZrO2@SiO2 via a modified Stöber method, Ceramics International 42:7583-7592.

- Yang X, Zhao N, Zhou Q, Cai C, Zhang X, Xu J (2013) Precise preparation of highly monodisperse ZrO2@SiO2 core-shell nanoparticles with adjustable refractive indeces, J. Mater. Chem. C 1:3359-3366.

- Widoniak J, Eiden-Assmann S, Maret G (2005) Synthesis and Characterization of Monodisperse Zirconia Particles, Eur. J. Inorg. Chem. 44:3149-3155.

Ester Barrachina

Universitat Jaume I, Spain

Title: Development of glass-ceramics glazes formulated from industrial residues

Time : 12:20-12:50

Biography:

Ester Barrachina worked in R&D in Minera Sabater S L (2000-2004) and dedicated to the exploitation of white clays for the ceramic sector. She is the R&D Director in Tierra Atomizada S A (2004-2012) and producer of spray-dried powder for the ceramic tiles industry, where she developed her Doctoral thesis totally focused on the industry. Since 2013 until now, she is a Researcher in the Research Group of Solid State Chemistry in the Department of Inorganic and Organic Chemistry of Universitat Jaume I, led by the full Professor Juan B Carda Castelló. Her research is focused on the development of ceramic and glass-ceramics materials from industrial residues as recycled glass, ceramic chamottes, ashes from the thermal power station, etc., in order to revalue them. She is an author of several articles published in scientific journals such as Ceramics International, Bulletin of the Spanish Society of Ceramics and Glass, Materials Letters, etc.

Abstract:

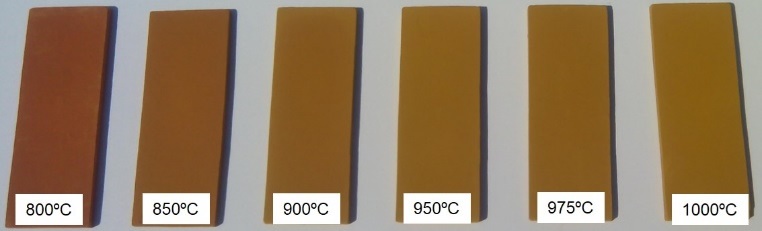

In order to revalorize industrial residues such as glass cullet waste, chamotte from defective tiles or fly ashes from a coal thermal plant, some compositions precursor of glass-ceramic materials have been formulated, using the diagrams used for the design of ceramic materials synthesized by petrurgic method (Gingsberg, Raschin-Tschetverikov and Lebedeva diagrams). The typical instrumental techniques (XRD, XRF, DTA/TG, dilatometer, particle size distribution by laser diffraction and heating microscope) have been used in order to characterize waste and compositions. Then, the TTT diagram (Time-Temperature-Transformation diagram) of each composition have been studied to find the optimum conditions to get the glass-ceramic glaze in the firing cycle of the porcelain stoneware tiles. Finally, the mechanic, chemical and magnetic properties have been studied in each case.

Figure 1: Glass-ceramic tiles formulated from industrial residues and fired at different temperatures to produce the devitrification of the precursor glass.

Recent Publications:

- Gómez-Cuaspud, Vera-López E, Carda J B, Barrachina E (2016) One-step hydrothermal synthesis of LaFeO3 perovskite for methane steam reforming. Reaction Kinetics, Mechanisms and Catalysis 120 (1): 167-179.

- Barrachina E, Núñez J A, Fraga D, Calvet I, Carda J B (2016) Development and characterisation of a new anti-slip glaze with smooth texture and easy-cleaning for porcelain. Journal of the Spanish Ceramic and Glass Society 2 (55): 79-85.

- Fraga D, Stoyanova Lyubenova T, Martí R, Calvet I, Barrachina E, Carda J B (2016) Ecologic ceramic substrates for CIGS solar cells. Ceramics International 6(42):7148-7154.

- Ouarsal R, Lachkar M, Dusek M, Barrachina E, Carda J B, El Bali B (2016) Crystal structure of NaCd(H2PO3)3 H2O and spectroscopic study of NaM(H2PO3)3 H2O, M = Mn, Co, Ni, Zn, Mg and Cd. Polyhedron 106:132-137.

- Calvet I, Barrachina E, Martí R, Fraga D, Stoyanova Lyubenova T, Carda J B (2015) Synthesis, deposition and crystal growth of CZTS nanoparticles onto ceramic tiles. Journal of the Spanish Ceramic and Glass Society 54: 175-180.

Rashmi Rani

Ecole Polytechnique, France

Title: Multiferroic and magnetoelectric properties of BCT-ZF ceramics

Time : 13:50-14:20

Biography:

Rashmi Rani has completed PhD dual degree in Physics (from India and Italy) under the Erasmus Mundus (European Commission) scholarship in May 2015. She has experience in synthesis and the morphological, structural and electrical characterization of electro-ceramics and nanocrystalline ceramics for memory device applications. Further, she has also worked extensively on ferroelectric thin-films, polymers and metal oxide nano-fibers for biomedical applications and tissue engineering. The core area of her experimental expertise is in preparation of electro-ceramics by solid state reaction, sol-gel technology and hydrothermal method, Microwave Assisted Radiant Heating (MARH), thin films, spin coating technique, electrospinning and electrodeposition. Her experience in experimental techniques is as follows: XRD, TEM, SEM, TGA-DSC, Impedance Spectroscopy, LCR Meter, D.C. resistivity, FTIR, Raman analysis and UV-Vis spectroscopy. She has published 13 research papers in international refereed journals.

Abstract:

Multiferroic BCT-ZF ceramics were prepared from ferromagnetic (FM) zinc ferrite (ZF) and ferroelectric (FE) barium calcium titanate (BCT) with different mole % age of x, ((1-x) BaO.96CaO.O4TiO3–(x) ZnFe2O4) by using solid state reaction method. The preliminary structural studies were carried out by using x-ray diffraction technique, which confirm that the samples have a tetragonal structure along with the cubic spinel ferrite phase at room temperature with the average crystallite size of 22-32 nm. Raman spectra of these composites also confirm the existence of BCT phase and ZF phase respectively. Room temperature ferroelectric characterizations have shown that the samples are ferroelectric along with an adequate magneto electric coupling of 10.85 mV/(cm.Oe). The strong dependence of electric parameters on applied magnetic DC bias fields provides a framework for the development of potential magneto electric devices. Also, the high sensitivity of magneto electric coupling to the applied AC magnetic field can be used for its application in magneto electric sensors.

A Poulon Quintin

Université de Bordeaux, France

Title: Tantalum nitride structure selection and carbon diffusion

Time : 14:20-14:50

Biography:

A Poulon Quintin is an Associate Professor at the University of Bordeaux and Institut de Chimie de la Matière Condensée de Bordeaux. She has a long experience in the correlation between process parameters, microstructure and properties of structural and functional materials. Her current interests range from the search for innovative multifunctional coatings, more exactly hard coatings, for applications in energy, aerospace and aeronautical industries. She is a specialist in fine characterization with an extended recognized experience in electronic microscopy and physico-chemical techniques.

Abstract:

Because of their unique electrical, mechanical and chemical properties, transition metal nitride thin films have attracted considerable attention in recent years. In particular, tantalum nitride (TaN) thin films are very promising materials due to their high thermal stability, hardness, chemical inertness and conductivity. TaN exhibits two crystallographic structures: Hexagonal and cubic. An accurate control of reactive magnetron sputtering deposition conditions allows us to isolate both phases. TaN thin films can be used as buffer layers and diffusion barriers against cobalt diffusion during diamond deposition on sintered WC-Co cutting tools. Its function is also supposed to control carbon diffusion phenomenon during the process in order to enhance diamond nucleation. In this study, we gauge the potentiality of the metastable face-centered-cubic and the stable hexagonal TaN phases on diamond nucleation. The potentiality of TaN to be carburized during the CVD diamond deposit process is discussed as the carbon diffusion phenomenon. The understanding of the specific responses of each TaN phase during the CVD process opens up new horizons for diamond coating performances.

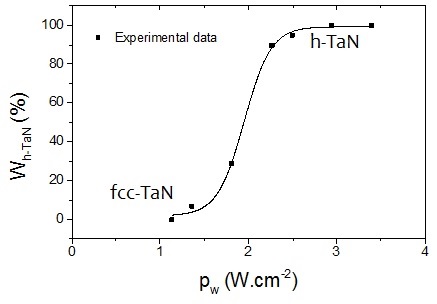

Figure 1: Evolution of the hexagonal TaN weight ratio as a function of target power density (reactive magnetron sputtering).

Recent Publications

1. B Le Gloannec, O Doyen, C Pouvreau, A Doghri, A Poulon Quintin (2016) Numerical simulation of upset resistance welding in rod to tube configuration: Required conditions and contact resistances determination. Journal of material processing technology 238:409–422.

2. M Cheviot, M Gouné, A Poulon Quintin (2015) Monitoring tantalum nitride thin film structure by reactive RF magnetron sputtering: Influence of processing parameters. Surface Coating and Technology 284:192–197.

3. A Poulon Quintin, C Faure, L Teulé Gay and J P Manaud (2015) Innovative solution to improve multilayer nano crystalline diamond coating adhesion. Applied Surface Science 331:27-34.

4. D Sidane, E Bousquet, O Devos, M Puiggali, M Touzet, V Vivier, A Poulon Quintin (2015) Local electrochemical study of friction stir welded aluminum alloy assembly. Journal of Electroanalytical Chemistry 737:206-211.

5. C Faure, A Hodroj, L Teulé Gay, J P Manaud and A Poulon Quintin (2013) Mechanisms of time-modulated polarized NCD growth. Surface and Coating Technology 222:97-103.

Yuliia Chabak

Priazovskyi State Technical University, Ukraine

Title: Carbides coatings deposited by new pulsed plasma technique

Time : 14:50-15:20

Biography:

Yuliia Chabak has graduated from Priazovskyi State Technical University (PSTU) in 2010 and she has got the PhD degree in Material Science in 2014. Currently, she is working at PSTU in position of Assistant Professor. Her research interests are in the fields of heat treatment and phase-structural transformations in high-alloyed cast irons, as well, she deals with surface modification and protective coating deposition using plasma-assisted techniques.

Abstract:

Statement of the Problem: Pulsed plasma treatment (PPT) is known for using for surface hardening of machine parts and tools. PPT is usually focused to modify the treated surface due to high speed of heating and cooling followed by the formation of fine crystalline martensite with increased hardness and wear performance. PPT with the use of electro-thermal axial plasma accelerator (ETPA) is quite new technique allowing to deposit the protective coatings with required properties depending on cathode material. Up to now, high-carbon alloyed steels and white cast irons were not used as the cathode material for ETPA plasma processing. The purpose of this study is to study the structure and properties of carbides coating formed using high-Cr cast iron and high-W high speed steel (HSS)

.

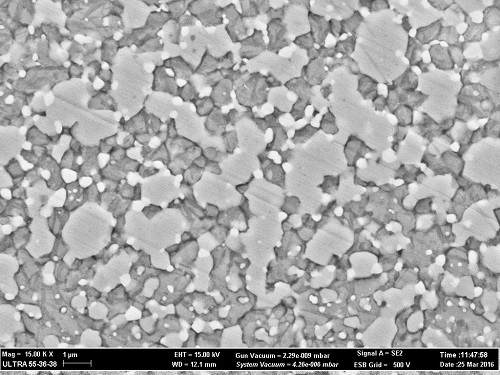

Methodology & Theoretical Orientation: The coatings were manufactured applying ETPA device. As the electrode material 28%Cr cast iron and 18%W T1HSS were used. The study was performed employing SEM, EDS, XRD, microhardness testing, after PPT post-heat treatment (950oC, 2 h) was used for structure improving.

Findings: Fe-C-Cr(W) and Fe-C-Cr-W coatings of 150-200 mm thickness were pulse plasma deposited using ETPA. Changing cathode material allowed to form layered coating structure which is coherent to substrate. Post-deposition heat treatment results in precipitation of Cr- and W-rich carbides phases M7C3, M3C2, M6C, M2C followed by the transformation of austenite into martensite. It was found that PPT using ETPA is accompanied with carbon enrichment of the coating which results in increasing carbides volume fraction to 50-70 %. This causes sharp increase of coating microhardness up to 1200-1500 HV.

Conclusion & Significance: PPT with ETPA combining post-heat treatment can be successfully applied for carbides coating deposition which is perspective approach for wear resistance improvement.

Figure 1: The W-rich carbides in the coating deposited using the cathode of T1 HSS

Recent Publications :

- Espallargas N, Mischler S (2011) Dry waer tribocorrosion mechanisms of pulse plasma nitrided NiCr. Wear 270: 464-471.

- Kolyada Yu, Fedun V (2015) Pulse electrothermal plasma accelerators and its application in scientific researches. Problems of Atomic Science and Technology 4: 325-330.

- Ozbek Y, Akbulut H, Durman M (2015) Surface behavior of AISI 4140 modified with the pulsed-plasma technique. Materials and Technology 49:441-445.

- Efremenko V, Chabak Yu, Lekatou A., Karantzalis A, Shimizu K, Fedun V, Azarkhov A, Efremenko A (20016). Pulsed plasma deposition of Fe-C-Cr-W coating on high-Cr-cast iron: Effect of layered morphology and heat treatment on the microstructure and hardness. Surface and Coatings Technology 304: 293–305.

- Chabak Yu, Fedun V, Shimizu K, Zurnadgy V, Efremenko V (2016) Phase-structural composition of coating obtained by pulsed plasma treatment using eroded cathode of T1 high speed steel. Problems of Atomic Science and Technology 102:102-106.

- Sessions: Ceramics and Composites | Materials and Innovative Processing Ideas | Bioceramics and Medical Applications

Location: Burgos

Chair

Piedad N de Aza

Universidad Miguel Hernández, Spain

Session Introduction

Chaoying Ni

University of Delaware, USA

Title: Structural and thermal properties of reaction bonded SiC/Si composite

Time : 15:20-15:50

Biography:

Chaoying Ni centers his research interest on the structural and property characterizations of advanced materials using Transmission Electron Microscopy (TEM) and Scanning Electron Microscopy (SEM). His expertise includes electron crystallography and e-beam associated spectroscopy. His active efforts are on the process-structure-property relationships of advanced composites, materials for energy or environment, mechanistic interpretation of thermal properties, mesoporous crystals, functionalized nanostructures and assemblies, thin films, interfaces and coherence growths.

Abstract:

The thermal conductivity (κ) of a reaction bonded SiC/Si composite as a function of SiC percentage and temperature was characterized. The κ value strongly associates with the SiC percentage and the inclusion of Si in SiC significantly decreases the κ value. The interfaces of both SiC/Si and SiC/SiC have significant contribution to the thermal resistivity. HRTEM confirms the existence of stacking faults and dislocations within the SiC phases near the interfacial region. In addition, an amorphous thin layer exists at the large angle grain boundary where significant lattice mismatch exists between SiC and Si during the crystal growth at the fabrication temperature. At a measurement temperature of about 1100°C, the κ value levels off and deviates from a general downward trend, suggesting a mechanism of structural evolution in the composite. The in-situ TEM heating test confirms the phase transformation of a-Si to crystalline Si at elevated temperatures

Recent Publications :

- Li X, Yan X, Zuo S, Lu X, Luo S, Z Li, Yao C, Ni C (2017) Construction of LaFe1−xMnxO3/attapulgite nanocomposite for photo-SCR of NOx at low temperature. Chemical Engineering Journal 320: 211-221.

- Yang Y, Yang H, Liu L, Li T, Yuan H, Ni C (2017) Effects of fluoride ion on the formation of earthworm-like mesoporous silica. Journal of the American Ceramic Society DOI: 10.1111/jace.14696.

- Zuo S, Chen Y, Liu W, Yao C, Li X, Li Z, Ni C, Liu X (2017) A facile and novel construction of attapulgite/Cu2O/Cu/g-C3N4 with enhanced photocatalytic activity for antibiotic degradation. Ceramics International 43 (3): 3324-3329.

- Chen J, Cai X, Yang D, Song D, Wang J, Jiang J, Ma A, Lv S, Hu MZ, Ni C (2017) Recent progress in stabilizing hybrid perovskites for solar cell applications. Journal of Power Sources 355: 98-133.

- Li X, Li F, Lu X, Zuo S, Yao C, Ni C (2017) Development of Bi2W1−xMoxO6/montmorillonite nanocomposite as efficient catalyst for photocatalytic desulfurization. Journal of Alloys and Compounds 709: 285-292.

Ming Xuan Gan

Nanyang Technological University, Singapore

Title: Consistency of 3D printing spodumene articles

Time : 16:10-16:40

Biography:

GAN Ming Xuan is a graduate student in the School of Mechanical and Aerospace Engineering of Nanyang Technological University. He received his Bachelor degree in Mechanical Engineering from Nanyang Technological University, Singapore. His research interests include optimisation of support structures and additive manufacturing of ceramics/glass-ceramics using the selective laser melting process.

Abstract:

Statement of the Problem: Two of the many issues in selective laser melting is the repeatability and consistency of the printed parts. In particular, the properties of the printed parts may vary with respect to the printing locations on the substrate plate. Moreover, part property variation can also occur between separate print jobs. Therefore, this study aims to study the part properties at different locations of the substrate plate.

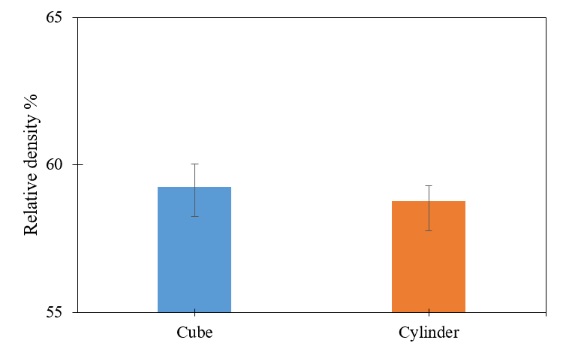

Methodology & Theoretical Orientation: We used selective laser melting to additive manufacture of 10 mm ×10 mm×10 mm cubic spodumene glass-ceramic articles. The relative density of these parts is then measured using the Archimedes method and tabulated. On a separate print job, cylinders of Ø12 mm × 12 mm were printed. As a rule of thumb, the relative density of these samples should be independent of geometry in order to prove the consistency of printing this material.

Findings: On average, the relative density of all the cubic samples was measured to be 59.231% with a standard deviation of 0.98%. Based on this average, the difference in relative densities at different locations was found to be less than 1%. The largest difference in relative density was calculated to be 3.98% at two different locations. Nevertheless, this shows that the relative densities of these parts printed at different locations were relatively consistent. Cylindrical samples printed were also measured to have very similar relative densities with the cubes.

Conclusion & Significance: In conclusion, with the correct set-up and processing conditions, glass-ceramic parts can be printed with considerable consistency in terms of relative density. This study also shows the consistency for two different geometries as both produced comparatively similar relative densities.

Figure.1: Comparison of relative density between cubic and cylindrical samples.

Recent Publications :

- C H Wong and M X Gan (2016) Selective laser melting of spodumene: An exploratory study, 2nd International Conference on Progress in Additive Manufacturing, Singapore,16 May 2016 – 19 May 2016

- M. X. Gan and C. H. Wong, “Effect of hatch spacing on the density of selectively laser melted spodumene,” 6th International Congress on Ceramics, Dresden, Germany, 21 August 2016 – 25 August 2016.

- C H Wong and M X Gan (2016) Practical support structures for selective laser melting. Journal of Materials Processing Technology 238: 474-484.

Piedad N de Aza

Universidad Miguel Hernández, Spain

Title: Biphasic Si-Ca-P ceramic for regenerative medicine: scaffold processing and biocompatibility

Time : 16:40-17:10

Biography:

De Aza P N received her Doctoral degree in Chemistry-Ceramin in 1995. She did a Post-doctoral degree at the IRC in Biomaterials at the Queen Mary College, University of London (UK) working on in vitro and in vivo behavior of bioceramics. At this moment, she is the Chair of the Materials Science, Optic and Electronic Technology department, Professor of Materials Science and Metallurgical Engineering and Researcher at the Bioengineering Institute at the Miguel Hernandez de Elche University.

Abstract:

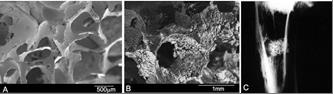

The present study refers to the preparation and biocompatibility characterization of a biphasic Si-Ca-P scaffolds to be used as matrices for bone regeneration or as-specific release vehicles. Ceramics are widely used for bone tissue engineering purposes and in this study, a Si-Ca-P biphasic porous scaffold, with nominal composition 28.39 wt% 7CaOP2O52SiO2-71.61wt% 5CaOP2O5SiO2 was produced using the polymer replication method of homogeneous mixtures of fine synthetic 7CaOP2O52SiO and 5CaOP2O5SiO2 powders. Polyurethane sponges were used as templates and impregnated with ceramic slurry at different ratios, and sintered at 1450ºC during 2 hours with 5ºC/min as heating and cooling rates. The characteristics of the Si-Ca-P porous scaffolds and respective powder used as starting material were investigated by using SEM, particle size distribution, XRD and Hg porosimetry techniques. It was possible to produce highly porous biphasic Si-Ca-P scaffolds presenting micro and macropores and pore interconnectivity. In addition, bioactivity was evaluated by examining in vitro apatite formation in simulated body fluid (SBF) for several periods of time. The experimental results demonstrated that, during soaking in SBF the porous surface of the ceramic became coated by HA-like layer after 6 hours. Also, in vivo biocompatibility was tested by implantation in NZ rabbits´ tibia. All animals survived the 6 months study period without evidence of inflammation or infection at the implantation site and strong adhesion between bone and the scaffolds was observed. The first results of in vivo tests on NZ rabbits showed good biocompatibility and osteointegration of the porous scaffolds implants, with higher osteoconductive properties and earlier bioresorption

Figure 1: (A) SEM view of the biphasic Si-Ca-P scaffolds (B) scaffold after 5 days SBF soaking and (C) antero-posterior X-ray of the bone section contained the implant after 3 month implantation.

Recent Publications :

- Ros-Tarraga P, Mazón P, Meseguer-Olmo L, De Aza PN (2016) Revising the subsystem nurse’s A–phase-silicocarnotite within the system Ca3(PO4)2–Ca2SiO4. Materials 9 (5): 322.

- Ros-Tarraga P, Mazón P, Rodriguez MA, Meseguer-Olmo L, De Aza PN (2016) Novel resorbable and osteoconductive calcium silicophosphate scaffold induced bone formation. Materials 9 (9):785.

- Rabadan-Ros R, Velasquez P, Meseguer-Olmo L, De Aza PN (2016) Morphological and structural study of a novel porous nurse´s A ceramic with osteoconductive properties for tissue engineering.Materials 9 (6): 474.

- Maté-Sánchez de Val JE, Calvo-Guirado JL, Granero Marín JM, Gomez- Moreno G, Mazón P, De Aza PN (2016) Material characterization and in vivo behavior of dicalcium silicate cement modified with phosphorus. Ceram. Int. 42(1): 952-960.

- Lugo GJ, Mazón, P, De Aza PN (2016) Material processing of a new calcium silicophosphate ceramic. Ceram. Int. 42: 673-680.

Sara Ahmadi

Amirkabir University of Technology, Iran

Title: Developing of a 3D printing method to fabricate a bone replacement hydroxyapatite/polycaprolactone scaffolds

Biography:

Sara Ahmadi has her expertise in developing novel drug delivery systems for target and controlled drug release studies. She graduated with a PhD degree in December 2016 from University of Wollongong in Australia. The main focus of her research during PhD was using polymeric devices as drug carries for treating CNS disease. She won the National Elite Foundation Postdoctoral Fellowship of Iran in 2017. She started her Postdoctoral Research in 2017 in New Technologies Research Center of Amirkabir University of Technology. The basis of her Postdoctoral Research is developing novel composites aiming to on-demand delivery of NSAIDs drugs.

Abstract:

Recently, usage of 3D printing methods to fabricate all type of human organ has been considered. Among all of them, 3D printed scaffolds to be utilized as bone replacement implant have been investigated comprehensively. The advantage of this method is fabricating an implant with exact dimensions of the actual bone tissue. In addition, this method is faster than the conventional methods which surgeon used to apply to replace the injured or infected bone tissue. First of all, polycaprolactone with different concentrations of hydroxyapatite (0, 10%, 15% and 20%) were mixed completely. The HA/PCL composite was prepared with 40%, 50%, and 60% porosity. Then by using a spinneret, we transfer the HA/PCL composite to filament with a specific diameter (1.65-1.85 mm). We used these filaments to feed the 3D printer instrument. As a model, a femur bone of rabbit was used to design the scaffolds. The femur bone of rabbit was 3D scanned and transferred to Simplify 3D software to prepare the 3D printing pattern. The open source 3D printer printed the HA/PCL filament exactly similar to the rabbit bone. The mechanical properties of the 3D printed scaffold was determined and compared to femur rabbit bone. In terms of 3D printed scaffold characterization, the yield strength, stress-strain, force, stiffness, compressive modulus, and surface morphology of them have been studied.